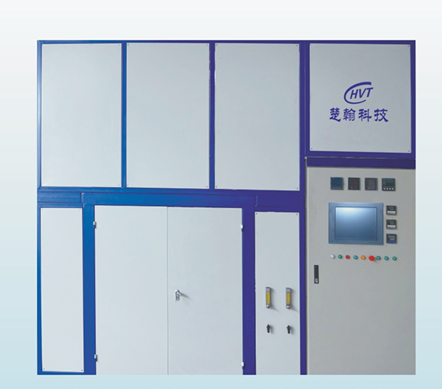

ipari kemencék

Az ipari kiváló hitelesített kátegazdálkodásunk az elme heatment technológia előterében áll, kiváló megoldásokat nyújtva a sokfele gyártási igényekhez. Több mint két évtizedes tapasztalattal rendelkezünk, amely során specializáltan foglalkozunk nagy teljesítményű ipari mályák tervezésével és gyártásával, melyek precíz hőmérséklet-ellenőrzést kombinálnak az energiahatékonysággal. A mályaink haladó digitális figyelőrendszereket tartalmaznak, ami konzisztens melegeloszlást és optimális feldolgozási feltételeket biztosít. A termékkategória batch típusú mályákat, folyamatos feldolgozású mályákat és egyedi megoldásokat tartalmaz, amelyek képesek 2000°C-os hőmérsékletig eljutni. Minden egység modern izolációs anyagokkal és intelligens vezérlő rendszerekkel rendelkezik, amelyek minimalizálják az energiaszállítást, miközben maximalizálják a termelékenységet. Szolgálunk számos iparágban, beleértve a repülőipart, az autóipart, a fémipart és a kerámiai ipart, specializált melegítő megoldásokkal a melegítési kezelés, sinterelés, áramlás és anyagvizsgálat alkalmazásaihoz. A mályaink több biztonsági jellemzővel vannak ellátva, beleértve az esetleges kikapcsoló rendszereket és a hőegyenletes ellenőrzéseket, hogy megbízható és biztonságos működést biztosítsanak. A moduláris tervezés lehetővé teszi a könnyű karbantartást és a jövőbeli frissítéseket, míg a robust építés hosszú távú tartóságot és konzisztens teljesítményt garantál.