induction heater factory

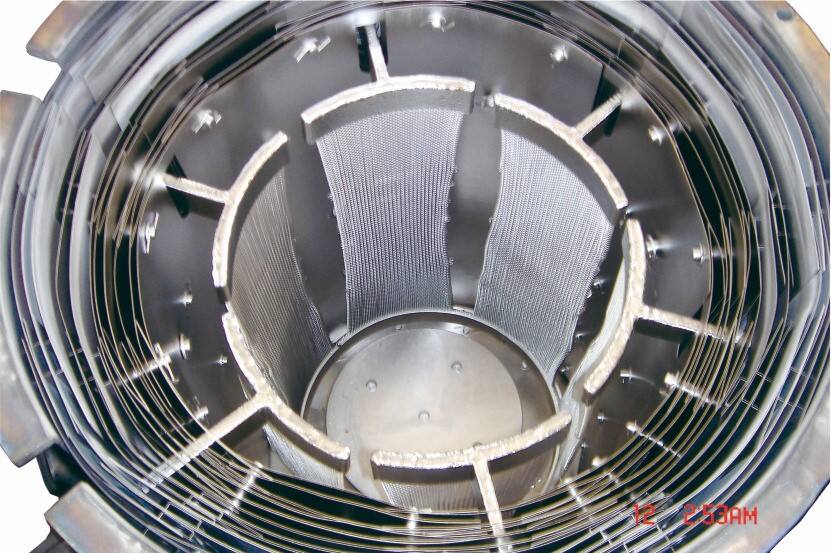

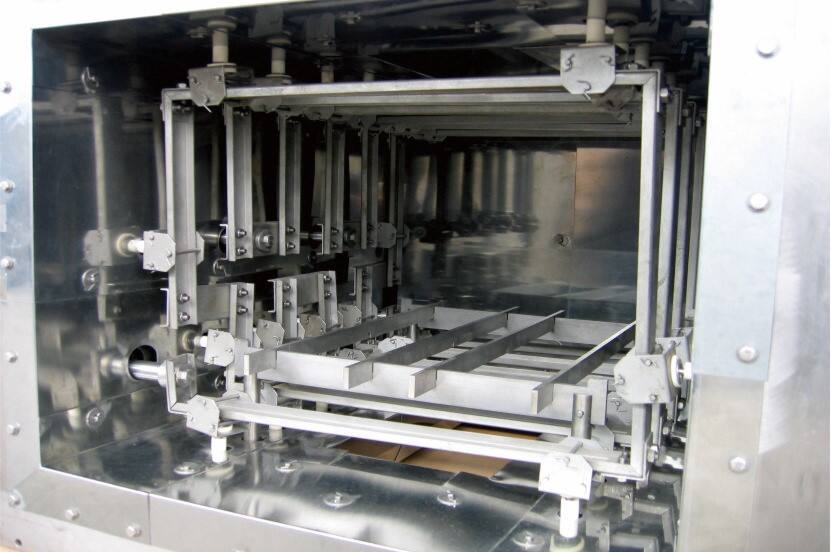

An induction heater factory represents a state-of-the-art manufacturing facility dedicated to producing advanced heating systems that utilize electromagnetic induction principles. These facilities integrate cutting-edge technology with precision engineering to create efficient heating solutions for various industrial applications. The factory encompasses multiple production lines equipped with automated systems, quality control stations, and testing facilities to ensure consistent product excellence. Modern induction heater factories employ advanced manufacturing processes, including CNC machining, automated assembly lines, and sophisticated testing equipment to produce high-frequency induction heating systems. These facilities specialize in manufacturing various induction heating components, from power supply units to cooling systems and work coils. The production environment maintains strict quality control measures, adhering to international manufacturing standards and safety protocols. The factory's capabilities extend to customizing solutions for specific industrial applications, including metal heat treating, brazing, melting, and hardening processes. With research and development departments, these facilities continuously innovate and improve their products to meet evolving industry demands and energy efficiency requirements.