induction heater manufacturer

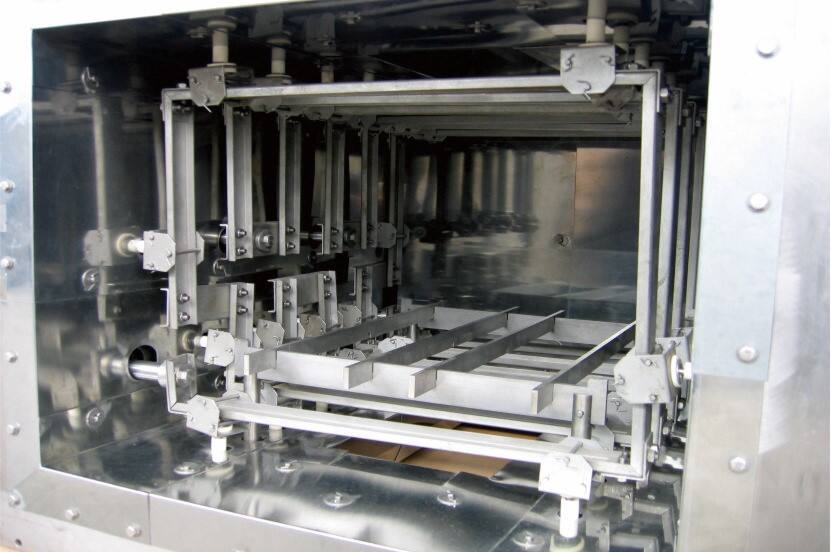

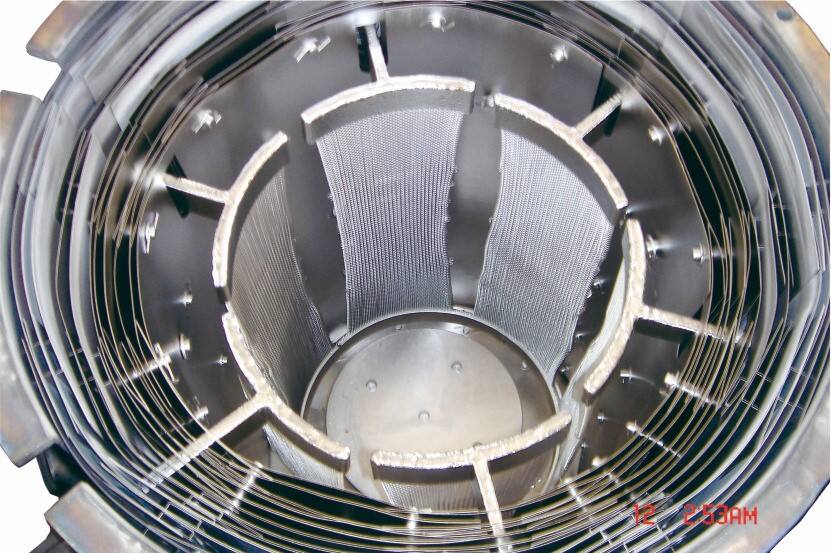

An induction heater manufacturer stands at the forefront of innovative heating technology, specializing in the design, production, and distribution of advanced induction heating systems. These manufacturers combine cutting-edge electromagnetic technology with precision engineering to deliver efficient heating solutions across various industries. Their product range typically includes both standard and customized induction heating equipment, from compact units for small-scale operations to industrial-grade systems for large manufacturing facilities. The manufacturing process incorporates state-of-the-art quality control measures, ensuring each unit meets rigorous safety and performance standards. These manufacturers excel in developing systems that offer precise temperature control, rapid heating capabilities, and energy-efficient operation. Their expertise extends to creating specialized solutions for diverse applications, including metal heat treatment, brazing, forging, and various industrial processes. Modern induction heater manufacturers also emphasize digital integration, incorporating smart controls and monitoring systems that enable real-time process management and data analysis. They maintain dedicated research and development teams focused on continuous innovation and improvement of their heating technologies, ensuring their products remain at the cutting edge of industry developments.