china induction heater

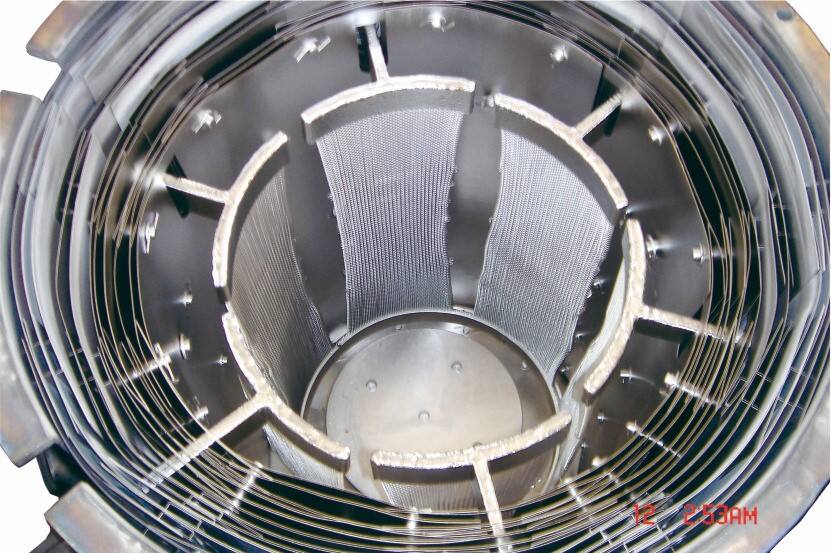

The China induction heater represents a cutting-edge heating solution that utilizes electromagnetic induction to generate precise and efficient heating. This innovative technology operates by creating an electromagnetic field that induces electrical currents within conductive materials, resulting in rapid and controlled heating. The system comprises advanced power electronics, copper coil inductors, and sophisticated temperature control mechanisms. These heaters are designed to deliver consistent heating performance across various applications, from industrial manufacturing to domestic use. The technology excels in providing instant heat generation, eliminating warm-up periods typically associated with conventional heating methods. What sets these units apart is their ability to achieve high energy efficiency, often reaching up to 90% conversion rates compared to traditional heating methods. Modern China induction heaters incorporate smart control systems that enable precise temperature regulation, programmable heating cycles, and real-time monitoring capabilities. They are equipped with multiple safety features, including overheating protection, current limiting mechanisms, and automatic shut-off systems. The versatility of these units makes them suitable for diverse applications, including metal heat treatment, brazing, forging, and various manufacturing processes. Additionally, they offer environmentally friendly heating solutions by reducing energy consumption and minimizing heat waste.