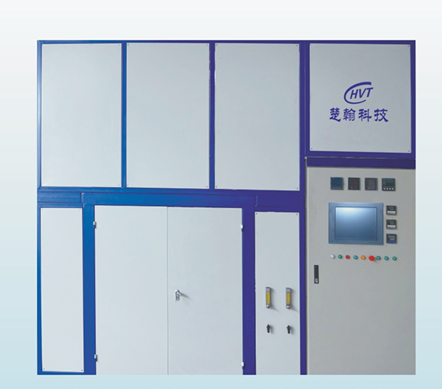

industrial furnace for sale

The industrial furnace for sale represents a cutting-edge solution in thermal processing equipment, engineered to deliver exceptional performance and reliability in diverse manufacturing environments. This state-of-the-art system features advanced temperature control mechanisms that ensure precise heat distribution and maintains consistent temperatures throughout the heating chamber. The furnace incorporates sophisticated digital controls that enable operators to program and monitor complex heating cycles with remarkable accuracy. With operating temperatures ranging from 300°F to 2200°F, this versatile unit accommodates various industrial applications, including heat treating, annealing, tempering, and stress relieving. The furnace's robust construction utilizes high-grade refractory materials and premium insulation, maximizing energy efficiency while minimizing heat loss. The system includes advanced safety features such as automatic shutdown protocols and temperature limit controllers, ensuring operator safety and equipment protection. Its modular design facilitates easy maintenance and future upgrades, while the integrated exhaust system effectively manages emissions and maintains workspace air quality. The furnace's spacious interior chamber offers ample capacity for large workpieces, and its heavy-duty loading mechanism ensures smooth material handling operations.